Although still relatively rare in the United States, large-scale municipal composting offers city and county governments the opportunity to divert solid waste streams, preserve needed landfill airspace, and produce revenue-generating soil amendments. The Howard County Composting Facility is a cutting-edge example of how municipalities can provide cost-effective processing of food waste, yard trim, and animal manure. EA supported facility design and permitting for the project, which serves as a roadmap for implementing a large-scale residential organics diversion program.

According to an EPA report from 2018, food waste represented more than 20% of municipal solid waste, with 2.6 million tons, or less than 5% being composted. Recent waste sorts conducted by Howard County have identified 27-30% organics content in municipal solid waste—a significant opportunity for reducing landfilled organics.

Pilot-Scale Testing

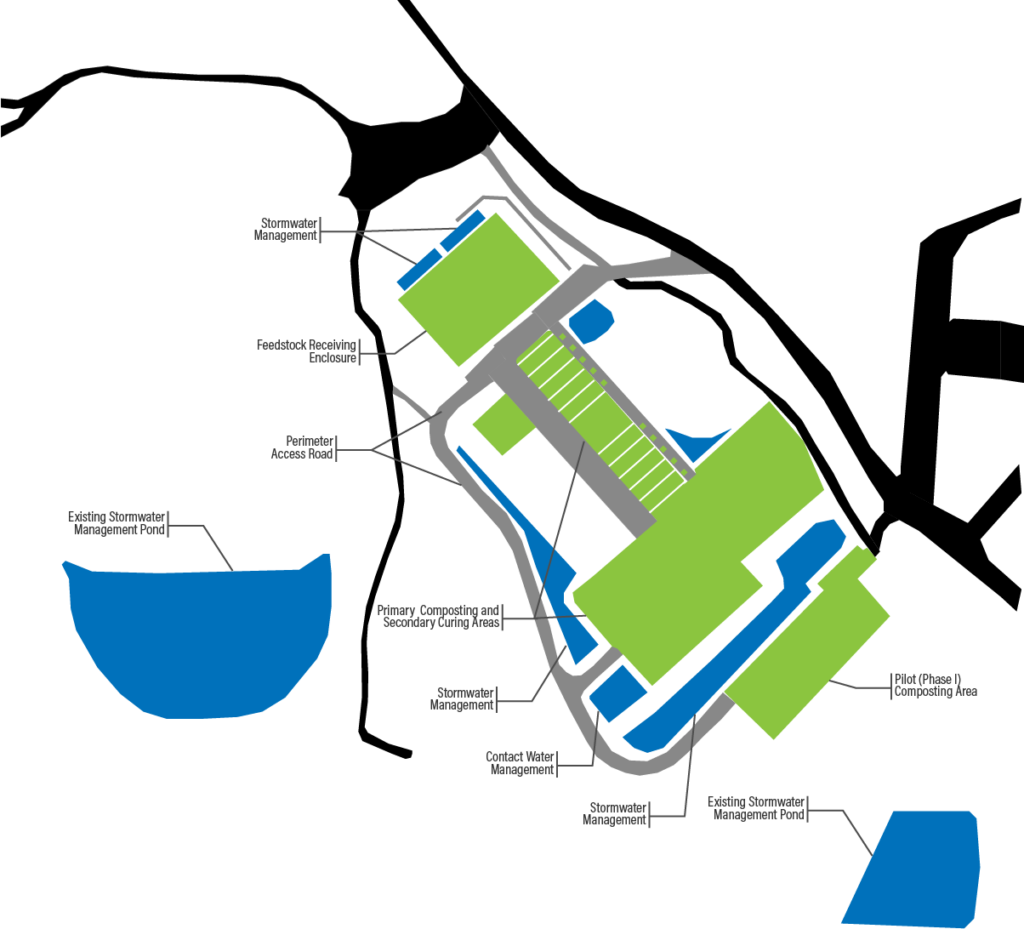

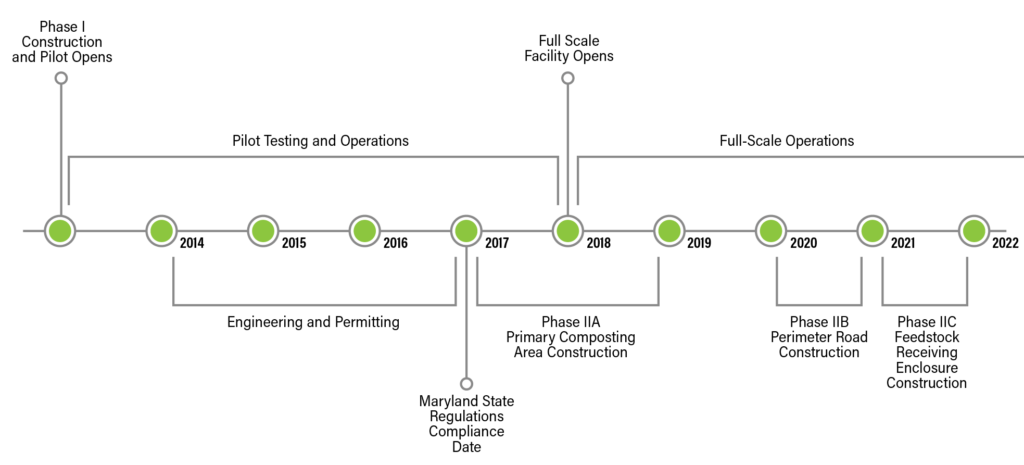

In 2013, the County built a pilot composting facility at the Alpha Ridge Landfill (link opens in a new tab). In line with the County’s commitment to improve sustainable materials management, a 2-acre portion of a 25-acre area of the site permitted for future landfill development was prioritized for composting. Developing the pilot facility onsite also maintained centralized management of solid waste at the Alpha Ridge Landfill site and eliminated the need to find a separate property for composting.

Howard County is home to approximately 320,000 people, with a quarter of the land area in farmland, including a strong agriculture and equestrian presence. Having feedstocks of horse manure, food scraps, and yard trim readily available, officials built a low-budget facility with an annual processing capacity of approximately 3,000 tons of material. Over 1 year of operations, the County confirmed the effectiveness of aerated static pile compost technology to meet the material curing requirements without producing significant odors. In addition, site personnel used the opportunity to practice site operations; understand the mechanics of moisture management and how to manage compost runoff; and determine the perfect compost mixture of leaves, food scraps, and manure, with little contamination.

This future-proofing approach ensured that investment into a larger processing facility could effectively meet the County’s, and ultimately residents’, waste needs. Moreover, the pilot-scale facility allowed for the buy-in of site operators and administrators, while ensuring a smooth transition to larger-scale operations with little-to-no learning curve that could potentially impact output or economics.

Scaling Up

The County’s long-term goal is to expand residential curbside collection of food scraps throughout the County, and support food waste diversion from Howard County Public Schools. Based on the pilot facility’s success, the County contracted EA to initiate design for the proposed 15-acre facility. Challenges included odor control, contact water management, and construction phasing.

The design included use of the County-procured technology from Engineered Compost Systems (link opens in a new tab). Aerated static pile technology requires two 40-horsepower blower motors, stainless-steel ductwork, trench drains, and process piping systems. Composting occurs in 10 bunkers, each measuring 26 feet wide by 80 feet long, with 10-foot high bunker walls, and holding approximately 700 cubic yards of material.

The feedstock receiving enclosure allows optimum material processing in a 1‑acre covered material receiving and grinding building, which is a fabric-tensioned steel structure open on two sides. Construction of the enclosure is expected to be complete in Fall 2022.

“The project required a multi-disciplinary approach, engaging EA’s civil, environmental, and stormwater engineers; subcontracted support for structural, mechanical, and electrical design by Dhillon Engineering, Inc.; and coordination with the County’s technology vendor.”

EA Project Manager Regina Cagle Irr, P.E.

Odor Control

As with many organics facilities, odor control is among the most important considerations throughout project design and development. The Howard County facility has residences located to the east, south, and west of the Alpha Ridge Landfill site, with the nearest neighbors located just 700 feet away. Site operations minimize odor generation potential by processing feedstocks promptly upon receipt, including grinding received material and placing it immediately within bunkers with a cover material (mulch or other “overs” from finished compost).

The composting technology incorporates a negative aeration to aid in processing, while managing moisture and odor. Each 40-horsepower blower services five bunkers and is computer-controlled to maintain optimum oxygen concentration and moisture control required for accelerated material decomposition. The aeration system is connected to each bunker through in-slab trench drains embedded in the bunker floors that allow co-management of aeration and contact water. Air is drawn down through the piles of material (negative aeration) and directed to an adjacent biofilter for treatment, consisting of 4 feet of a compost and wood mulch mix. This technology was selected in lieu of a positive aeration system, due primarily to its effectiveness at odor management, and has proven itself extremely effective while requiring minimum operations and maintenance.

Contact Water Management

The facility design was developed to meet Maryland’s composting requirements, which were promulgated during the design process, and required compliance by 1 January 2017. Regulations mandate careful management of contact water, which is nutrient-rich runoff from the composting process, to mitigate the potential for infiltration into the surrounding area. In addition to negative aeration, the design utilized the trench drains integrated into the bunker floors to facilitate collection and reuse of contact water.

Credit: Allan Myers

A valve vault located behind each bunker’s rear push wall hosts the hydraulic separation and pressure barriers necessary to separate contact water and direct it through below grade piping to a lined lagoon. In addition, the process design includes a network of utility piping through which contact water can be pumped to the feedstock receiving enclosure for reuse for material wetting during material receipt and grinding. In order to maintain compost at the necessary 40‑60% moisture content by weight, this innovative use of water reuse for material wetting is critical in making the process more sustainable. Alternative water supplies available for material wetting include stormwater from an adjacent pond and, as a last resort, potable water.

Construction Phasing

To match funding availability and accelerate earnings potential, construction was completed in multiple phases, beginning in Fall 2017. Since it was critical for the facility to operate at full-scale processing capacity as soon as possible, processing areas of the facility (e.g., primary composting area and process piping, etc.) were prioritized for construction in the first construction phase (Phase IIA), while the site perimeter road (Phase IIB) and material receiving enclosure (Phase IIC) were deferred to future construction phases (as approved by the regulator).

Proof of Concept

“When initiated in 2013, the full-scale facility development called for a significant investment in cutting-edge composting technology,” said Regina. “Since that time, the project has demonstrated that the revenue from compost sales and avoided costs of disposal are higher than the operational costs, making a strong case for waste diversion and organics management.”

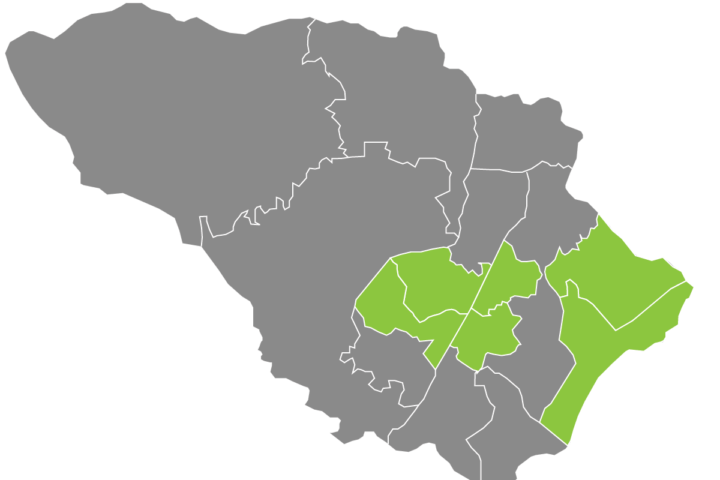

Through the County’s Feed the Green Bin residential collection program, 6 of the 15 existing trash and recycling zones in the County can now compost food scraps through residential curbside collection, with plans to expand County-wide.

Processing generates a beneficial soil amendment that can reduce the need for application of fertilizers, lessen erosion, and improve water retention in soils. The final product, HoCoGro Compost, is sold for $23 per cubic yard, and meets the County’s goal of material “made locally and spread locally.”

At full capacity, the tipping fee and airspace cost savings, combined with the revenue from compost sales, will reach nearly $1 million annually. On top of measurable cost savings, the facility creates additional value for the community through reduction of greenhouse gas by reducing landfill emissions and keeping the material local, avoiding the impact of waste transportation.

Among the few large-scale municipal composting facilities on the East Coast, this project successfully illustrates economic, operational, and sustainability benefits. It will serve as a guide for other jurisdictions as they look for alternative municipal solid waste management strategies and revenue streams.

Moving Forward with Municipal Composting

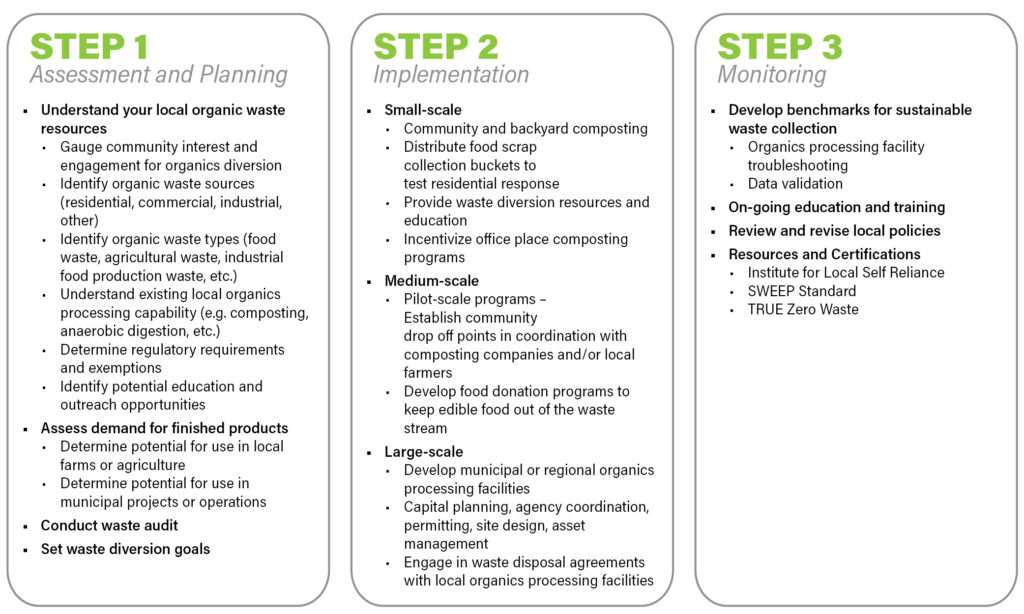

When evaluating the scale and associated challenges, municipalities should consider the regulatory environment and implementation strategy.

Both federal and state laws in relation to waste management are changing. Total statewide yard trim bans exist in many states. Commercial or overall food waste bans are in place or in development along the West Coast and in the Northeast. Several states have instituted aggressive mandates or legislation for food scrap collection and diversion from landfills. Federal compost regulations are in development for presentation to the House of Representatives. In addition, many cities have set diversion goals in pursuit of achieving zero food and/or total waste.

With these new directives, officials should consider a three-step strategy for composting at any scale:

Depending on the size and scale of the program, municipalities can access a host of different funding resources, including federal grants through EPA and U.S. Department of Agriculture. Many states also offer grants and other funding mechanisms to support the development of food waste diversion programs.

For more information on municipal composting, contact EA’s Regina Cagle Irr or visit EPA.gov to access their documentation on Types of Composting and Understanding the Process (link opens in a new tab).

The Howard County Compost Facility at Alpha Ridge Landfill was recognized as Project of the Year by the County Engineers Association of Maryland.

Contact Us