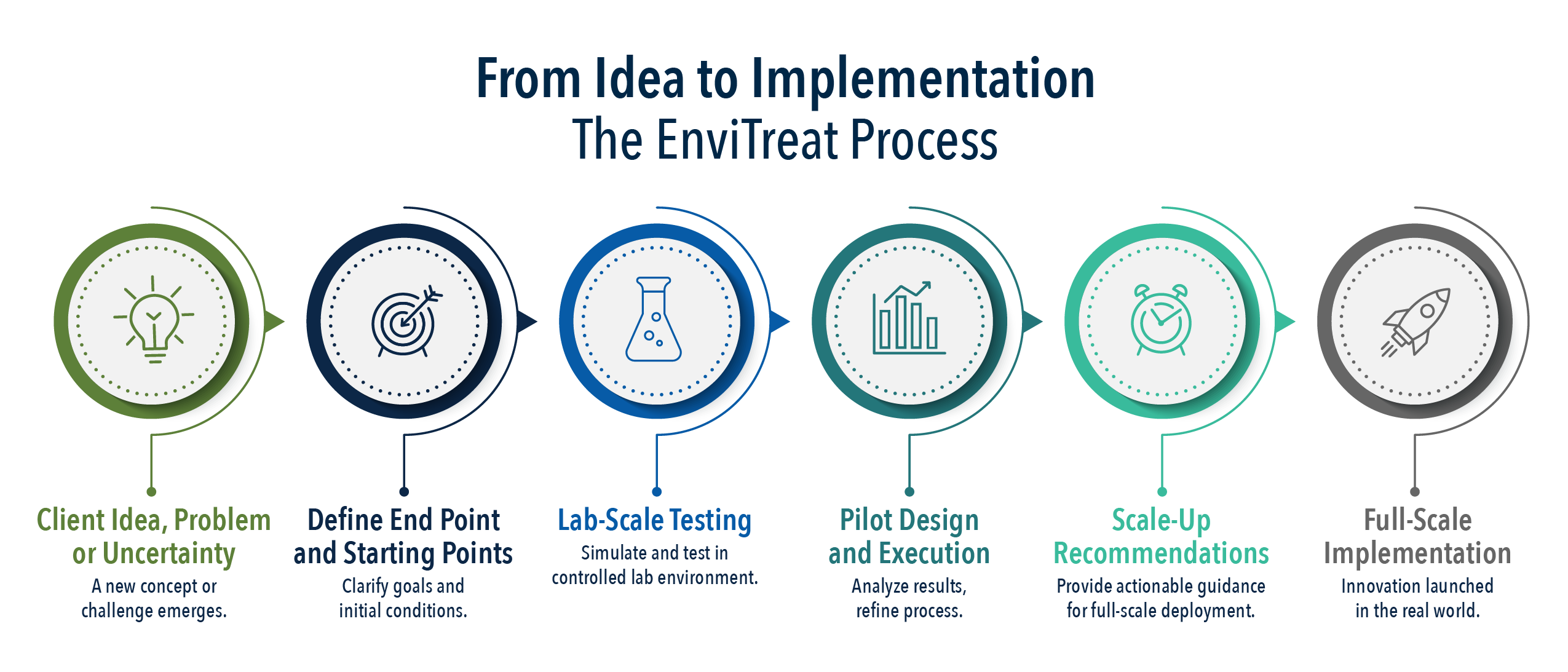

In wastewater treatment, the journey from concept to implementation is guided by clear steps and purposeful innovation, leading to impactful solutions. Whether the goal is to commercialize a new product or improve an existing process, the challenge is not just technical feasibility and data validation, but also scalability, cost, and operational realism. Most organizations have a vision for what they want to achieve, but the path from idea to reliable, full-scale application is often unclear. EA’s EnviTreat laboratory specializes in transforming these challenges into opportunities by guiding clients through the process of testing, refining, and scaling their innovations for maximum impact. This article will outline technical considerations and practical steps that underpin successful technology validation through lab‑scale wastewater treatment pilot testing for full‑scale implementation.

Defining the Problem and the End Point

Every project starts with a problem and a desired outcome. The first questions to ask are:

- Where do we start (influent characteristics, process constraints)?

- What are the project goals (target effluent quality, cost savings, efficiency, automation, other operational goals)?

- What are the constraints of the project (money, space, time, simplicity, etc.)?

The answers to these provide project clarity and a determination for how lab-scale tests are designed. Testing design is critical so that test results reflect treatment behavior in the full-scale system. EnviTreat’s mission is to ensure that results from the lab-scale systems have “similitude” and behave similarly at full-scale as in the laboratory. This requires deep experience with full-scale systems. There are laboratories that can provide raw data. EnviTreat provides not only the data but also the determination of how that data can be used as well as implemented.

Engineering Lab-Scale Tests for Real-World Relevance

A recurring technical challenge is ensuring that what works in the laboratory will work at full-scale. This is not trivial. The goal is to ensure the lab test reflects the complexities of the real system—reflecting the practical limitations of mixing, pumping, chemical dosing, and process variability. This approach prevents unrealistic results and ensures that recommendations are grounded in operational reality.

For instance, when working with granular activated carbon (GAC), the hydraulic environment in a 10-foot vessel is vastly different than a 1-centimeter tube in the lab. To address this, EnviTreat adjusts the granule size and flow regime so that mass transfer and contact times are representative of full-scale conditions. Similarly, centrifugation tests are calibrated to match industrial equipment capabilities, avoiding the pitfall of over-optimizing in the lab.

Adaptive Piloting and Cost-Efficient Experimentation

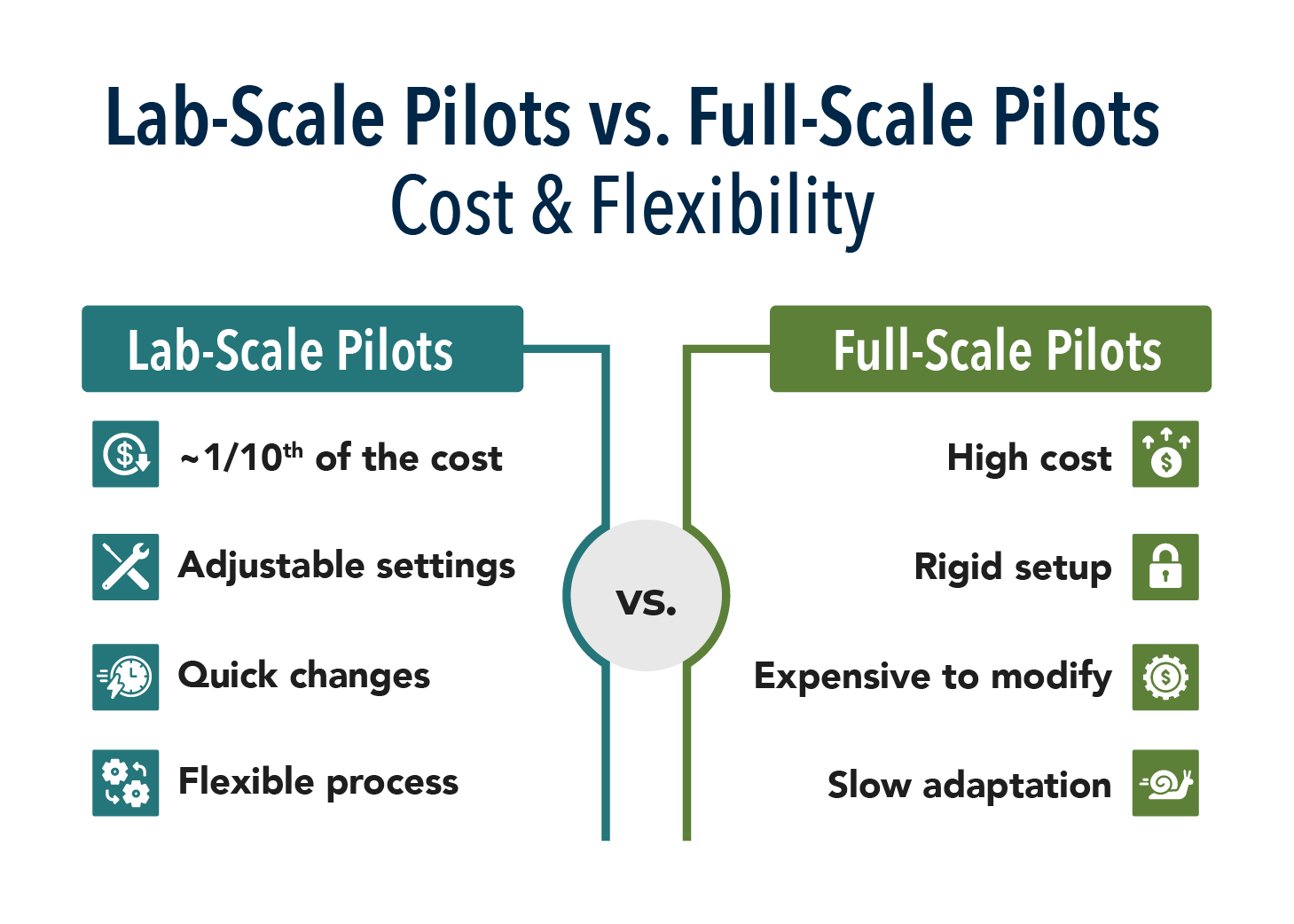

One of the advantages of lab-scale pilots is the ability to adapt quickly and cost-effectively. Full-scale pilots are expensive and inflexible. A single change can require significant rework. Modular lab setups allow analysts to reconfigure reactors, pumps, and process trains on the fly, responding to new data or client requests in real time. An extensive inventory of equipment enables mimicking of entire process trains (anaerobic, aerobic, membrane filtration, etc.), not just isolated steps.

High Strength Contamination Destruction Case Study: In a recent project, EnviTreat was tasked with destroying 1,4-dioxane at concentrations much higher than equipment vendors had previously attempted. By testing four different treatment methods at lab-scale, a viable approach was identified and proven viable, validated in a vendor pilot, and ultimately implemented at full-scale—despite initial skepticism from equipment suppliers.

Mimicking Full-Scale Process Trains

Clients often request that their entire process be mimicked, not just a single unit operation. While it is impossible to replicate every nuance of a full-scale plant, EnviTreat can assemble a treatment train in the lab units that closely approximates the conceptual process train. This provides engineers and end users with greater confidence, as they can observe system behavior as a whole and not just in isolated steps. The analogy is that a car’s engine and wheels may work separately, but confidence comes from seeing the car drive down the road.

Data, Deliverables, and Scale-Up Support

The output of this work is not simply a “yes/no” on treatability. EnviTreat recommends providing detailed performance data, operational parameters, and conceptual designs for scale-up, including recommendations for tank sizes, pump specifications, chemical usage, and process integration. This data set forms the basis for scale-up calculations, equipment specification, and conceptual process design. When required, effluent and residual samples should be provided for further client-side analysis.

Technical deliverables can be tailored to the needs of both consulting engineers and end users. For clients without in-house engineering, EnviTreat can also support design and startup, or it can collaborate with external consultants to ensure a smooth transition from laboratory validation to full-scale plant deployment.

Bridging Laboratory Analysis and Real-World Applications

A distinguishing feature of EnviTreat’s methodology is expertise in laboratory test design/operation, engineering design/construction, and operational/troubleshooting experience. Many labs can generate data but lack the practical experience to contextualize results within the constraints of full-scale systems. Conversely, field operators may understand process limitations but lack the tools to rigorously evaluate new technologies at bench-scale. EA’s integrated approach facilitates experiment design that is both scientifically rigorous and operationally relevant.

Continuous Learning and Knowledge Integration

Exposure to a wide range of technologies—through client projects, literature review, and industry collaboration—keeps EnviTreat at the forefront of innovation. Often, a question from one client leads to a solution for another client, as connections are made across industries and applications. Openness and willingness to experiment are essential for advancing the field.

Resource Recovery Case Study: In a project, a waste stream excluded from a vendor’s process was found to be rich in protein and bone. By proposing recovery and valorization, several new revenue streams were created for the client.

Conclusion: Lab‑Scale Wastewater Treatment Pilot Testing for Full‑Scale Implementation

Testing and scaling new ideas in wastewater treatment is fundamentally an engineering challenge—one that requires technical rigor, adaptability, and a deep understanding of both laboratory science and real-world operations. By focusing on practical validation, adaptive piloting, and transparent data sharing, organizations can move from concept to implementation with confidence.

For those facing novel treatment challenges or seeking to validate new technologies, the right questions—and the right experiments—can reveal solutions that are both robust and innovative.

For More Information

Matt Frigon, PhD

Matt Frigon, PhD

EnviTreat Laboratory Director

Email

Contact Us