Common Issues, Remedies, and Opportunities for Improving Efficiency

Efficient operation of a municipal enhanced nutrient removal (ENR) wastewater treatment plant requires a fundamental understanding of the various processes and potential issues that could affect treatment outcomes. EA’s EnviTreat laboratory, originally founded in 1995, focuses on treatability evaluations of wastewater—biological, physical, and chemical—as well as operational diagnoses, and process optimization. In this downloadable white paper, Director Matt Frigon, PhD, discusses common issues, remedies, and opportunities for improving operational efficiency based on EnviTreat’s work with both the municipal and industrial wastewater treatment plant processes. Primary findings include, but are not limited to:

- Reliance on Mixed Liquor Suspended Solids (MLSS) or Mixed Liquor Volatile Suspended Solids (MLVSS) as the main parameter for operational process control can result in poor plant performance.

- Plant operation using Solids Retention Time (SRT) will enable a system to self-regulate according to loading and conditions.

- Chemical use surveys are the best and cheapest way to identify toxicity issues related to chemical inputs to the system.

- Oxygen Uptake Rate (OUR) setpoint control is a potentially effective approach to monitor for and quickly recover from toxic impacts to biological treatment systems.

ENR Wastewater Treatment Plant Process Concerns

Operators typically rely on MLSS or MLVSS concentrations as the primary metric for plant operation without considering active organism percentages. A normal healthy plan would expect 15‑30 percent of their MLSS to be active organisms. In municipal and industrial plants with long SRTs, the proportion is lower—frequently between 4 and 5 percent. This concern is often observed in membrane bioreactor (MBR) systems. MBRs are regularly operated at mixed liquor concentrations between 8,000 and 12,000 when the loading on the plant does not justify such high solids levels. Most facilities are overdesigned, meaning the plant design MLSS is higher than needed for effective treatment. Unnecessarily high MLSS can have negative impacts on plant performance.

System SRT Calculation and Control

SRT calculations are frequently completed solely using the aeration basin volume instead of the volume of all sludge basins in operation at the plant. Recycle ratios at ENR plants are often set high so that sludge is well mixed throughout the system. Using this parameter only for the aeration basin discharge volume in the calculation results in wasting just a fraction of the amount of sludge needed to maintain a certain SRT. Calculated wasting volume must include the aeration basin, pre- and post-anoxic, and anaerobic/fermentation zones as applicable.

Control can be achieved easily and consistently by wasting directly from the aeration basin. Many plants are set up to waste from the underflow system because the sludge is more concentrated. This reduces the amount of water that must be decanted from the digester. However, the concentration of sludge in underflow is variable and will change with temperature, loading, and flow rate through the plant. By wasting from the aeration basin, the system will self-adjust the MLSS to maintain a consistent SRT, which helps maximize performance of the treatment reactor.

Toxic Impact of Chemicals

Although toxic chemicals primarily impact industrial plants, they also may play a role in municipal systems that accept industrial discharges. These include municipal systems receiving influent from sources, such as landfill leachates, that are similar to industrial discharges. Commonly identified chemicals of concern, which are capable of eliciting a range of operational issues, include peroxyacetic acid, quaternary ammonium compounds, amines, surfactants, hypochlorite, and salts. A chemical use survey is often the fastest, most effective, and most economical way to evaluate chemical of concern loading and toxicity. In the absence of data about chemical type or loading as with complex waste streams, toxicity testing can be used to assess acceptable loading rates on a particular treatment system.

OUR (Oxygen Uptake Rate) Setpoint Control and System Recovery

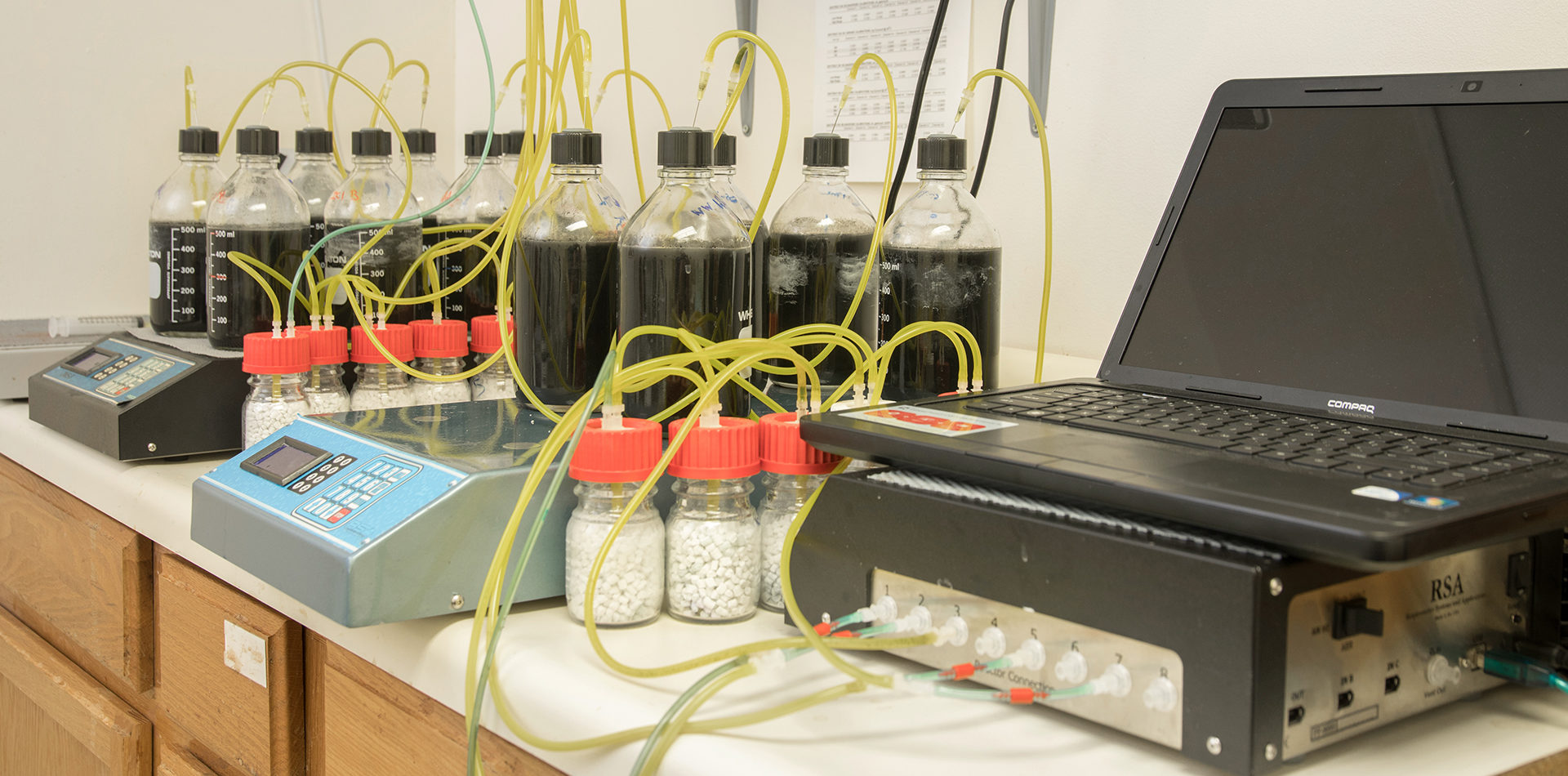

When toxic impacts affect active organisms in biological systems, the amount of time for organisms to degrade material may show significant delay or extension. Days to weeks may be required for treatment conditions to stabilize and return to normal. EnviTreat operated a pilot-scale reactor to measure baseline OUR of an aerobic reactor to evaluate biological process acceleration of a reactor recovering from toxicity impacts. A concurrent sludge storage reactor was operated to house sludge needed for the testing. System recovery was then accelerated by the addition of biomass from the sludge storage reactor.

Download the White Paper to Learn More

This paper was presented by EnviTreat Director Matt Frigon, PhD, at the Tri-Association Conference in August 2021.

Abstract:

The move toward enhanced nutrient removal (ENR) in wastewater treatment plants has been gaining ground for some time and is the future of wastewater treatment. Proper operation of ENR plants requires an understanding of the fundamentals behind their operation and the issues that may arise that could cause these systems to have poor or inadequate treatment outcomes or failure. This paper is intended to briefly address these issues. An introduction to biological operations for carbon, ammonia, and nitrogen removal is presented. In addition, operational controls based on solids retention time (SRT), the effects of varying SRT, and proper control of SRT are discussed. A method for optimizing SRT using oxygen uptake rates is presented. The importance of macro- (nitrogen and phosphorus) and micro-nutrients (trace minerals) and their effects on plant performance is described. The impact of industrial discharges to a municipal plant—especially chemicals such as peroxyacetic acid and quaternary ammonium compounds (Quats)—and their effect on optimum oxygen uptake rate (OUR) and SRT is also described. Finally, case studies are presented throughout the paper to illustrate topics and findings discussed.

Contact Us